Maximizing Supply Chain Resilience: Strategies and Insights for Navigating Global Uncertainties

- Marco Lopez

- Jan 11, 2024

- 3 min read

Introduction: The Critical Importance of Supply Chain Resilience

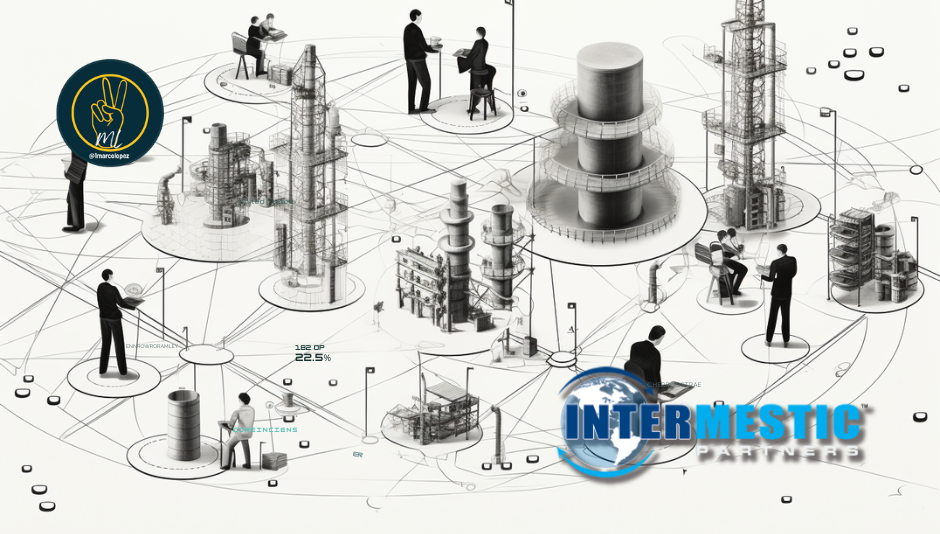

The agility, efficiency, and resilience of global supply chains play a pivotal role in businesses' capacity to keep pace in an increasingly volatile and unpredictable economic environment. Unprecedented disruptions and uncertainties exemplified by the COVID-19 pandemic heighten vulnerabilities, underscoring the critical need for robust supply chain resilience. This article shines a light on the objectives and mechanisms for achieving this resilience, delving into the practicalities of risk mitigation and business continuity preservation.

The Role of Risk Management in Enhancing Supply Chain Resilience

Handling risk begins by evaluating probable uncertainties and determining possible scenarios. Equipped with this knowledge, it is easier to plan and prepare appropriate responses in advance.

Strategies such as supplier diversification are particularly useful in managing risks, reducing dependencies on a single supplier, and thereby countering potential supply interruptions. Additionally, contingency planning enables businesses to proactively address various unforeseen circumstances, allowing them to maintain operations and mitigate negative impacts.

A Framework for Enhancing Supply Chain Resilience

Developments on the international stage have led to a consensus on creating a systematic approach for enhancing supply chain resilience. The World Economic Forum outlined a framework with key areas such as visibility and transparency, agility and flexibility, collaboration, and risk assessment and mitigation. Central to this framework is the need for proactive measures to identify and tackle vulnerabilities in the supply chain.

Visibility within the supply chain allows stakeholders to observe operations in real-time, enabling decisive and timely action to counter emerging threats. An agile and flexible approach further bolsters resilience, allowing businesses to adapt quickly to changing circumstances. Furthermore, through active cooperation and partnerships, businesses can foster a unified approach to combating unexpected situations, thus reducing resultant impacts.

Navigating Supply Chain Risks in a Volatile World

Identifying and assessing risks at the earliest possible stage mitigates potential disruptions and safeguards operations. Implementing risk mitigation measures helps stave off negative consequences but also highlights opportunities that may drive growth and innovation. Successful risk management relies on continuous monitoring to detect threats promptly and integrate lessons learned into future strategies.

The disruption of the COVID-19 pandemic is a significant case study for understanding risk management in a volatile world, offering essential lessons on resilience and the role of agility, visibility, and cooperation in maintaining business continuity. A detailed exploration of these lessons will follow in the second part of this blog.

Resilience Lessons from the COVID-19 Pandemic

The COVID-19 pandemic significantly impacted global supply chains providing valuable insights into building resilience. The speed at which disruptions can occur and the scale of their impacts makes agility the key to maintaining operational continuity. An agile supply chain can rapidly pivot in response to changes, thereby mitigating disruption impacts. Meanwhile, visibility across the entire supply chain facilitates swift detection of disruptions and accelerates response times. Collaborating with supply chain partners underpins successful crisis management by sharing risks and combining strengths to tackle challenges.

Technology’s Role in Enhancing Supply Chain Resilience

As we shift towards Industry 4.0, the role of technology in enhancing supply chain resilience gains significance. The transformative power of artificial intelligence, blockchain, and the Internet of Things (IoT) is central to this resilience. These technologies can radically improve supply chain visibility, traceability, and responsiveness.

Artificial Intelligence can automate and optimize supply chain processes while providing data analytics for informed decision-making. The blockchain ensures data integrity across supply chain networks, bolstering reliability and transparency. IoT devices enhance real-time monitoring capabilities, detect anomalies, and facilitate rapid responses to disruptions.

The Significance of Supplier Relationship Management

Trust and shared success are the building blocks of robust supplier relationships. Strategies such as collaboration, communication, risk sharing, and supplier development are key to success.

A strong supplier relationship goes beyond financial transactions, integrating suppliers into strategic plans and day-to-day operations. Shared risks and benefits can foster a healthy, long-term relationship that can better withstand external shocks. Open communication channels lead to transparency, while supplier development helps to adapt to changes in the business environment.

Conclusion: The Imperative of Proactiveness and Resilience

As we navigate the ever-changing business landscape, the imperative of proactiveness and resilience in supply chains becomes clear. It's not just about understanding potential risks but actively planning for them and embracing technology for enhanced data integrity and real-time visibility.

The insights shared in this article underscore the value of strong supplier relationships, collaboration, risk management, and adaptability to ensure operational continuity. Building a robust supply chain capable of meeting the challenges posed by disruptions and uncertainties is essential.

For organizations looking to deepen their understanding and capabilities in supply chain resilience, Intermestic Partners stands as a beacon of expertise in the field. With their extensive experience and innovative approaches, Intermestic Partners can provide tailored strategies that align with the unique needs of different industries and organizations. We invite readers to collaborate with Intermestic Partners to fortify their supply chain resilience and navigate the complexities of today’s global economy effectively.

.png)

Comments